Fibers

Today’s synthetic fibers allow ropes to be custom made to suit the individual purpose.

Nautilus Braids carries the following fibers:

Nylon

Nylon has up to 8gms/denier tenacity with a specific gravity of 1.14 (which means it sinks) in fresh and salt water. Good UV resistance. Does not absorb water. Melts at 260°C. Has up to 40% stretch at break.

Polyester

Again, this has 8-9gms/denier tenacity but with a specific gravity of 1.38 (which means it sinks). Good UV resistance. Does not absorb water. Resistant to acids and alkali. Melts at 255°C. Will stretch to 30% at break but generally has less stretch than nylon. White Polyester is stronger than coloured Polyester.

Polyethylene

Polyethylene is usually extruded as a monofilament and is available in 500 or 1000 denier. It has a specific gravity of 0.91-0.94 (depending on blend) so it floats. Melts at 120°C. Relative low strength at 1.84 -3.4gms/denier. UV resistance is good. Mainly used for ski ropes and the like. Will stretch to 65% at break.

Polypropylene

Polypropylene is normally used in lower quality ropes but can be extruded in a slit film or a fiber. The specific gravity is 0.855 so it is quite buoyant and floats. It has a low melting point at 160°C. Tenacity is 3.5-4.0gms/denier but it can have a higher tenacity 5.0gms/denier.

Ultra High Molecular Weight Polyethylene (UHMWPE)

Ultra High Molecular Weight Polyethylene (UHMWPE) is one of the strongest fibers known to man. UHMWPE is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene (HMPE), it has extremely long chains resulting in a very tough material, with high impact strength.

There are many manufacturers that claim various similar strengths of fiber, some of which do not live up to their claims while others do. UHMWPE has a tenacity of 35-39gms/denier and a very low stretch 2-5% at break. Although it has very low stretch, it will creep if left under tension. UHMWPE tends to get stronger as it creeps, until it starts to loose strength with use. It has a specific gravity of 0.97 which means it floats. Very good light fastness. Melts at 147°C.

Vectran

Vectran is a thermo tropic crystalline fiber. Strength of 25gms/denier with no or very little stretch. It is sensitive to sunlight with poor UV stability. It has a very high melting point 400°C and is often used in sheets that are required to slip on drums where heat generation is high. It has a high specific gravity of 1.37gms/denier, so it will sink in most solutions. It is a high modulus Aramid fiber and has a specific gravity of 1.45 and a tenacity of 19gms/denier. It is used in ropes for its high melting temperature of 550°C. Elongation at break is 2.4%.

Kevlar

Kevlar is a lightweight, high strength para-aramid fiber which is cut and heat resistant (up to 430 degrees centigrade). It has a density of approx. 1.44 and strength of 23 gms/denier. If using Kevlar, we recommend it should only be used as a core material and used with a protective outer layer as it is not particularly UV resistant.

Breaking Loads

Nautilus Braids has its own strength testing facility for testing ropes up to 14 tonnes. This provides the ability to compare strengths of various fibers and their elasticity/stretch. This is important when determining which rope to use for which application. Our breaking loads tend to be on the conservative side. Being able to test different constructions and fibers allows us to improve our braids and develop new products.

The following graph shows the breaking strengths and stretch characteristics for a range of fibers – Polyester, Nylon, Polypropylene, Vectran and Ultra High Molecular Weight Polyethylene.

Pitch and the Effects on Braids

Pitch is a measurement in Millimeters used in the braiding industry and is the advancement of a rope through a braiding machine in one complete revolution of the carriers. More correctly, it is the angle of the yarn from the longitudinal axis of the rope. The larger the pitch, the closer the yarns are to parallel and thus provide less stretch.

Pitch has a very large effect on a rope’s characteristics – how easy it is to splice, its elasticity, its flexibility and durability.

We have carried out many strength tests at Nautilus and found the optimum pitch for each diameter of rope, both outer and center.

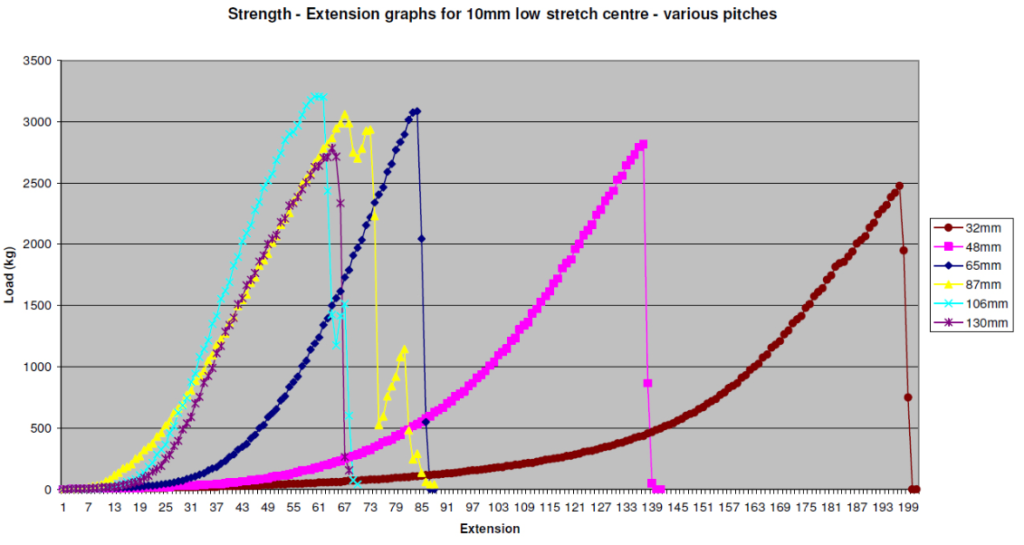

The graph below shows the effect of pitch on stretch for a range of 10mm UHMWPE centers.

Interesting Technical Data…

Splicing – Why it is so important?

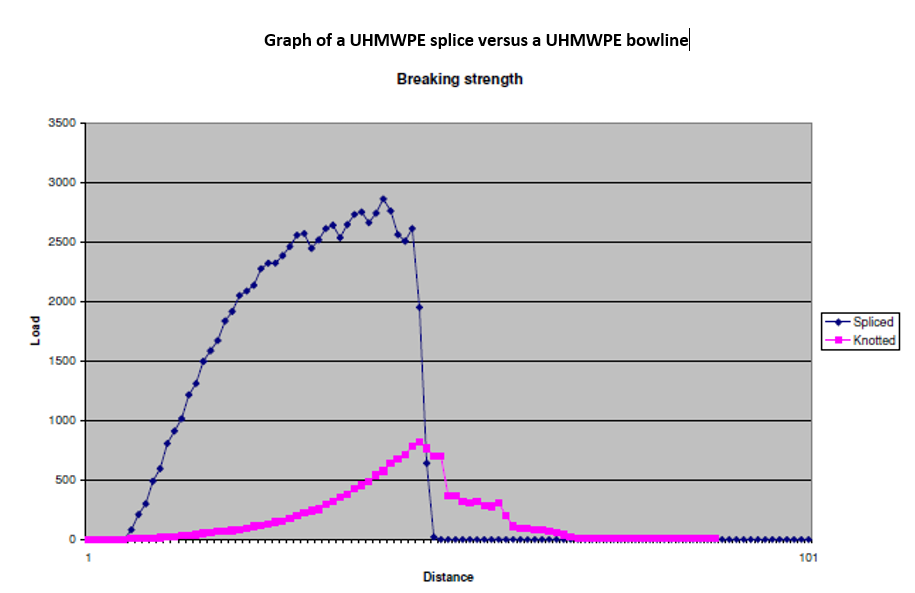

Using the right splice is important when determining breaking loads. We don’t recommend using a knot as this can lower the strength of all ropes by at least 50%. This is because knots have a very high centre of curvature when the rope wraps around the same rope in a knot.

We use different types of splices for different ropes. See below.

1. Ultra High Molecular Polyethylene (UHMWPE) ropes get stronger as they are used up to a point (after some years of use) where they start to deteriorate. Typically, on an 8mm winch rope, the increase in strength with use may be as high as 800kg.

2. In the test standards, there are different tests – a cyclic test and a straight break test. Most braiding companies quote the cyclic test as their claimed strength.

3. Always use splicing for UHMWPE ropes. For single braids, it is best to use a Brummel splice with a long tapered tail (at least 400mm long is necessary). For double braids, it is best use a double braid UHMWPE eye splice.

4. While it is not so important due to the small amount of fibre stretch, polyester braids should also be spliced rather than knotted.

5. The tight bends in the rope when knotted create pressure points where the braid will fail.

We recommend four different splicing techniques:

1) Brummel Eye Splice

2) Non–stretch Core Double Braid Eye Splice

3) 100% Polyester or Nylon Double Braid Eye Splice

4) Multiplait Splicing

The graph below illustrates the difference in strength of a non-stretch test sample with and without a knot tied in the rope.

Breaking Strength of Spliced and Knotted 10mm UHMWPE Fiber Core

Splicing Instructions

We are often asked how to splice ropes! With so many different fibers available, there are several different ways to splice ropes.

Click on our link below for step-by-step instructions to splice Ultra High Molecular Weight Polyethylene/winch ropes, polyester ropes, nylon and multiplait ropes.

Click here: http://nautilusbraids.co.nz/brummel-splicing/